| |

| New |

Automation for Marble Polishing Machine - Fidko installed PLC controlled automation for a marble polishing machine in "Mermeren Kombinat" - Prilep...

Read more |

Rectifiers for batteries - Fidko produces regulated chargers for rechargeable batteries that provide charging and maintaining of the batteries according to the desired feature.

Read more |

MB-600 - Fully automatic flour packing machine

Read more |

SCADA system - Fidko has fully automated the conveyor transport system in "Skopski Leguri" and installed a SCADA system which enables better control, efficiency, reliability...

Read more |

|

Production line for metal segments for transmission towers

|

In the first half of year 2008 our team realized full replacement

on twenty year old computer directioned automatic production line

for metal segments for grill pillars in department CRS - Kicevo

for Emo - Ohrid.

The productions line process is fully automatic and it involves

production of iron L - profil segments, from which grill pillars

for electrical pilon (transmission tower) and similar metal constructions

are composed. For example, the giant cross on Vodno hill near Skopje.

This project involved solving the following problems:

- Replacement of old computer system for programming based

on 286 technology, with modern computer system using application

developed with new Microsoft technologies, using Dot Net Framework

2.0.

- Replacement of old automation system based on electrical

modules with newest technology with Programmable Logic Controllers

(PLC) and interface modules.

- Galvanic separation and logical connection of the commands

from the new automation equipment to the previous contactor

disposition for control of the existing pneumatic and hydraulic

executive components of the system.

- Replacement of electromotor drive with direct current direction

with modern vector AC 3 phase motor.

|

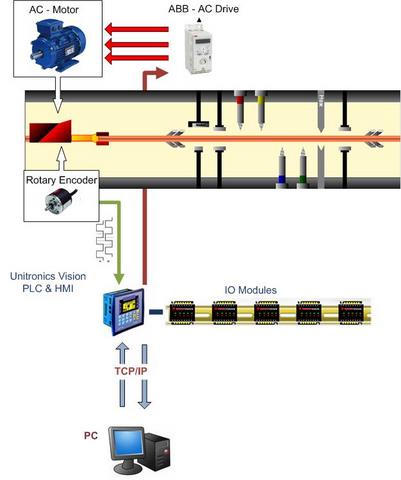

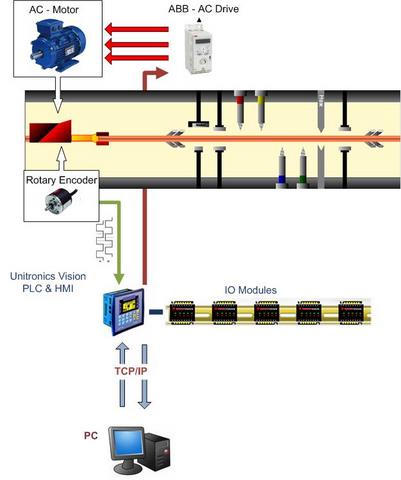

Direction of electromotor drive

|

|

Positioning the drilled profiles on horizontal axes is conducted

with a mechanical hand mounted on a mobile platform. The hand holds

the profile with pneumatic pliers. Positioning of the mobile platform

provides translator offset of the metal profile, which can be drilled

in extent of sixteen meters. For moving the mobile platform there

was a DC motor with permanent magnets for 130 V voltage and 504

A maximal current.

Our solution is based on 3 phase servomotor 2.2 kW and vector drive

for its direction. The power decrement of the drive motor is about

20 times, and it dousn't degenerate the characteristics of the drive,

but opposite of that, they stay on same level as they were before.

This is provided by modern vector regulation. The AC drive is directly

commanded from a PLC, witch use incremental encoder as a callback

information for positioning of the mobile platform .

With this solution we achieved:

- Drive for the mobile platform, without current picks and

low energy spend

- Reliable and robust(fault resistance) drive,

- High precission positioning of the mobile platform with

maximal error of +/- 0.25 mm.

|

Automatic for direction the line

|

Our engineers created a system for controlling the process line

with a PLC, external I/O modules and standard electric relay and

contactors for output devices.

This system use modern PLC's, programmed in Ladder logic like a

part of world standards for building SCADA (Supervisory Control

And Data Acquisition)systems.

With this we achieved:

- Easy upgradable system

- Easy maintenance of the automatic line

- Complete fullfilment of the client's demands

Equipment

PLC's and external modules are a standard equipment for systems

involving automatic regulation of an industrial process.

We use equipment from a reliable vendor for production of PLCs and

I/O modules - Unitronics.

The full process control on this line is provided from one PLC and

four I/O modules.

Programmable Logical Controllers are real time.

They regulate the process of manufacture drilled mettal profiles.

All PLCs are programmed, for manual and automatic mode, with

all restrictions and validation for secure work .

Programming and Communications

Unitronics provide communication

between Programmable Logic Controllers and PC with TCP/IP (30 years

old reliable communication protocol). Their drivers, made for that

purpose, are used by our application to exchange data from PC to

PLC and visa versa.

The program loaded in the PLC can be easily replaced with newer

and every future change or future upgrade can be done in the simplest

way.

With this we provide permanent and stabile solution for a long period.

|

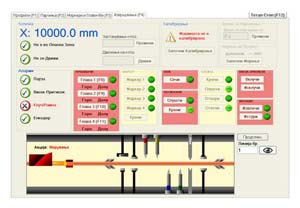

User application software

|

|

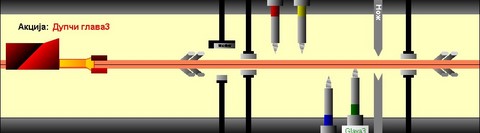

The application software offers it's user simple and efficient

way for parameters setting, process monitoring and command execution.

The entire process of process control and monitoring is followed

by graphic representations of the industrial process. The shape

of the metal profile and all actions that will be executed while

processing it are graphically represented by picture drawings. This

drawings is dynamically updated when a new action is added or a

change is made. Also there is an animation of the process while

the process is running.

The program offers several workings modes. They are automatic, step

by step and manual. In manual mode the user executes command by

his decision. In other modes, the software defines the steps of

execution and their order.

During the process execution, the worker is ensured from taking

actions that can provide material or machine damage. This is made

by validation of entered values via checking the data range, data

type and implementation of data constrains.

For software development we used Microsoft .NET framework 2.0. The

software written in C# and the Database platform is MS Access 2003.

We used ethernet and the vendor's PLC driver for cimmunication between

the PLC and the PC software.

|

|